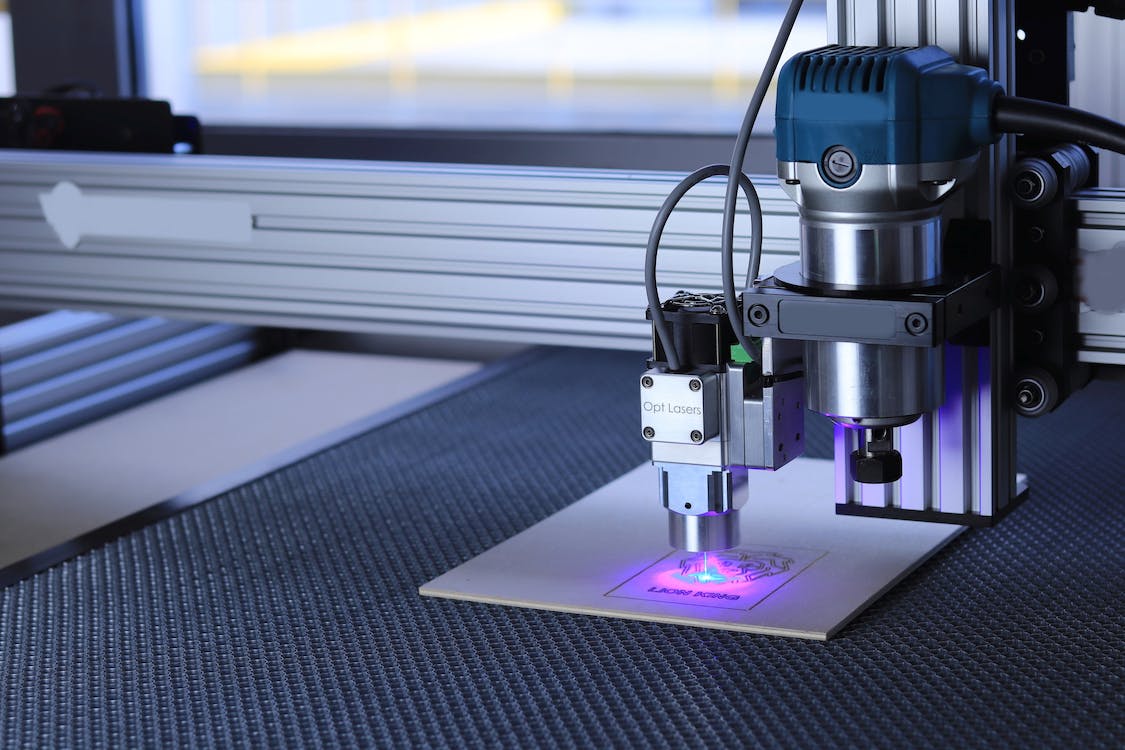

DXF (Drawing Exchange Format) files serve as the foundation of laser cutting, but mastering advanced techniques goes beyond simply creating and manipulating DXF files. It involves delving into sophisticated methods and approaches to achieve intricate designs, complex effects, and innovative outcomes in laser cutting projects. This guide delves into advanced techniques that go beyond dxf file for laser cutting, exploring new horizons in the realm of laser cutting.

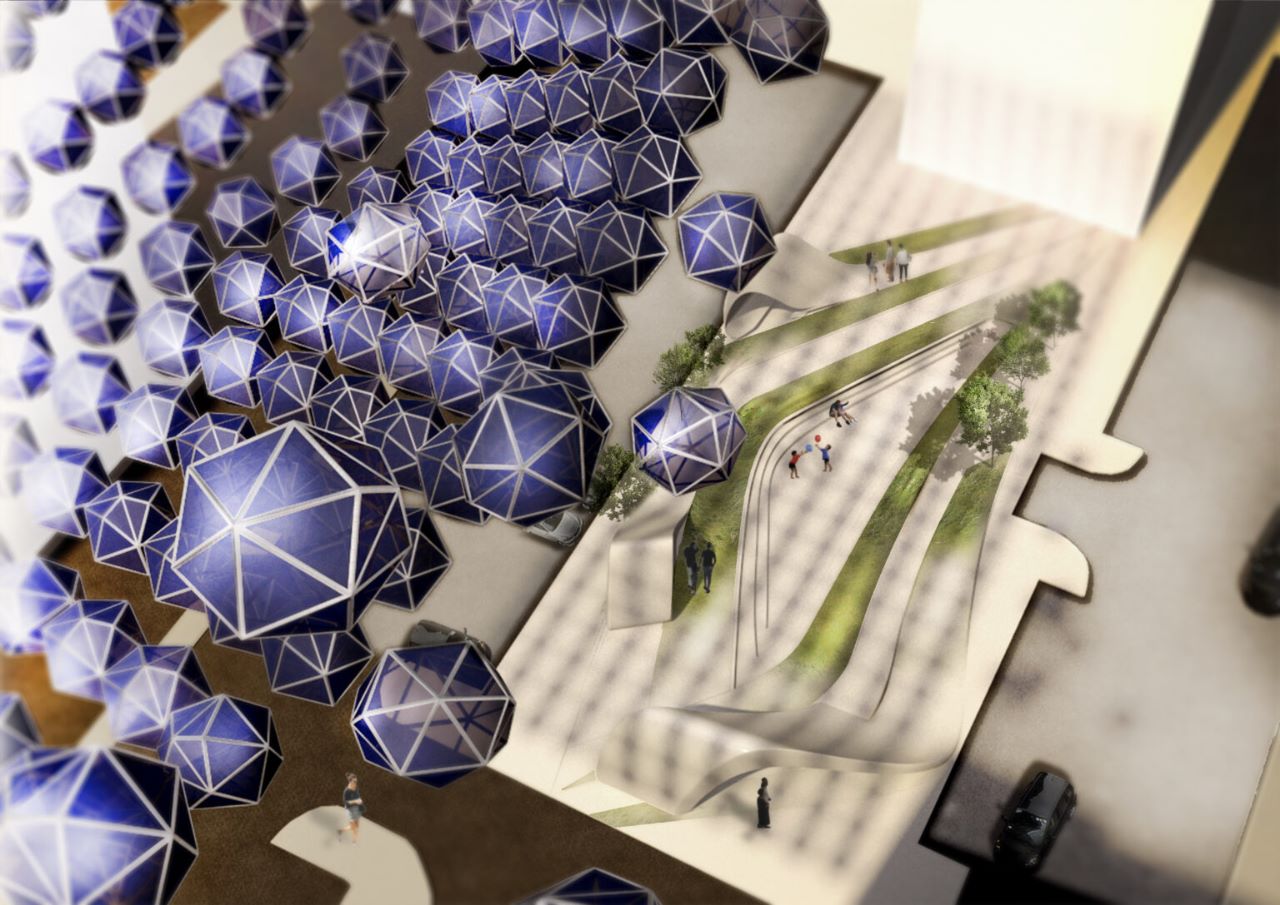

One advanced technique in laser cutting is the use of parametric design software to create dynamic and adaptive designs. Parametric design allows designers to create designs that respond intelligently to changes in parameters such as size, shape, or material properties. This enables designers to create intricate patterns, complex geometries, and adaptive structures that would be difficult or impossible to achieve using traditional design methods. By leveraging parametric design software, designers can push the boundaries of what is possible in laser cutting, creating designs that are not only visually stunning but also highly functional and adaptable.

Another advanced technique in laser cutting is the use of multi-axis cutting machines to achieve intricate three-dimensional designs. Unlike traditional laser cutting machines, which operate on a two-dimensional plane, multi-axis machines are capable of moving the laser head in multiple directions, allowing for more complex cutting paths and greater design freedom. This enables designers to create intricate 3D shapes, sculptural forms, and textured surfaces that add depth and dimension to their laser cutting projects. By mastering multi-axis cutting techniques, designers can unlock new possibilities for creativity and expression in laser cutting.

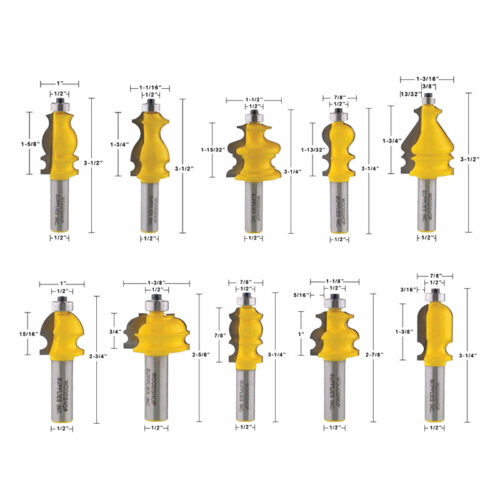

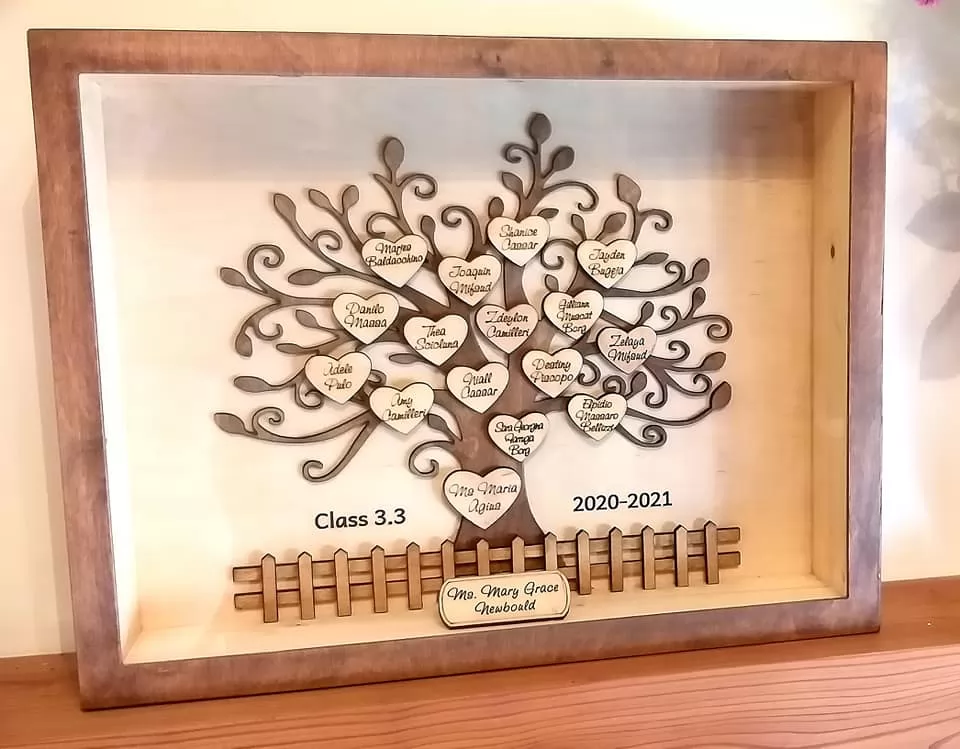

Additionally, advanced techniques such as inlaying, layering, and hybrid fabrication processes can be used to create more complex and dynamic designs in laser cutting projects. Inlaying involves embedding one material into another to create contrast and depth in the final design, while layering involves stacking multiple layers of material to create intricate patterns or textures. Hybrid fabrication processes combine laser cutting with other manufacturing techniques such as 3D printing or CNC machining to create hybrid objects that blend different materials and processes seamlessly. By exploring these advanced techniques, designers can push the boundaries of what is possible in laser cutting, creating designs that are truly unique and innovative.

In conclusion, mastering advanced techniques in laser cutting goes beyond DXF files, delving into sophisticated methods and approaches that enable designers to achieve intricate designs, complex effects, and innovative outcomes. By exploring parametric design, multi-axis cutting, inlaying, layering, and hybrid fabrication processes, designers can unlock new possibilities for creativity and expression in laser cutting projects, pushing the boundaries of what is possible and creating designs that are truly extraordinary

![Building Brilliance: Unveiling the Premier Residential Construction Experts in [Your City]](https://readingcoremag.net/wp-content/uploads/2023/12/Depositphotos_26374913_m-2015.jpg)

0