Small businesses often face unique challenges when it comes to material handling. While they may not have the extensive resources of larger enterprises, efficient material handling remains crucial for their operations. Fortunately, there are a variety of material handling equipment options available that are well-suited to the needs and budgets of small businesses. In this article, we will explore some of the essential material handling equipment options for small businesses.

1. Pallet Jacks: Pallet jacks, also known as pallet trucks, are a cost-effective and space-saving solution for small businesses. These manual or electric tools are used to lift and move palletized loads within a facility. Pallet jacks are especially valuable for loading and unloading shipments, as they reduce the need for manual lifting.

2. Hand Trucks: Hand trucks, also known as dolly carts or trolleys, are versatile and portable material handling tools. They are perfect for moving boxes, crates, and smaller loads. Hand trucks come in various configurations, including upright and convertible models, to accommodate different types of loads.

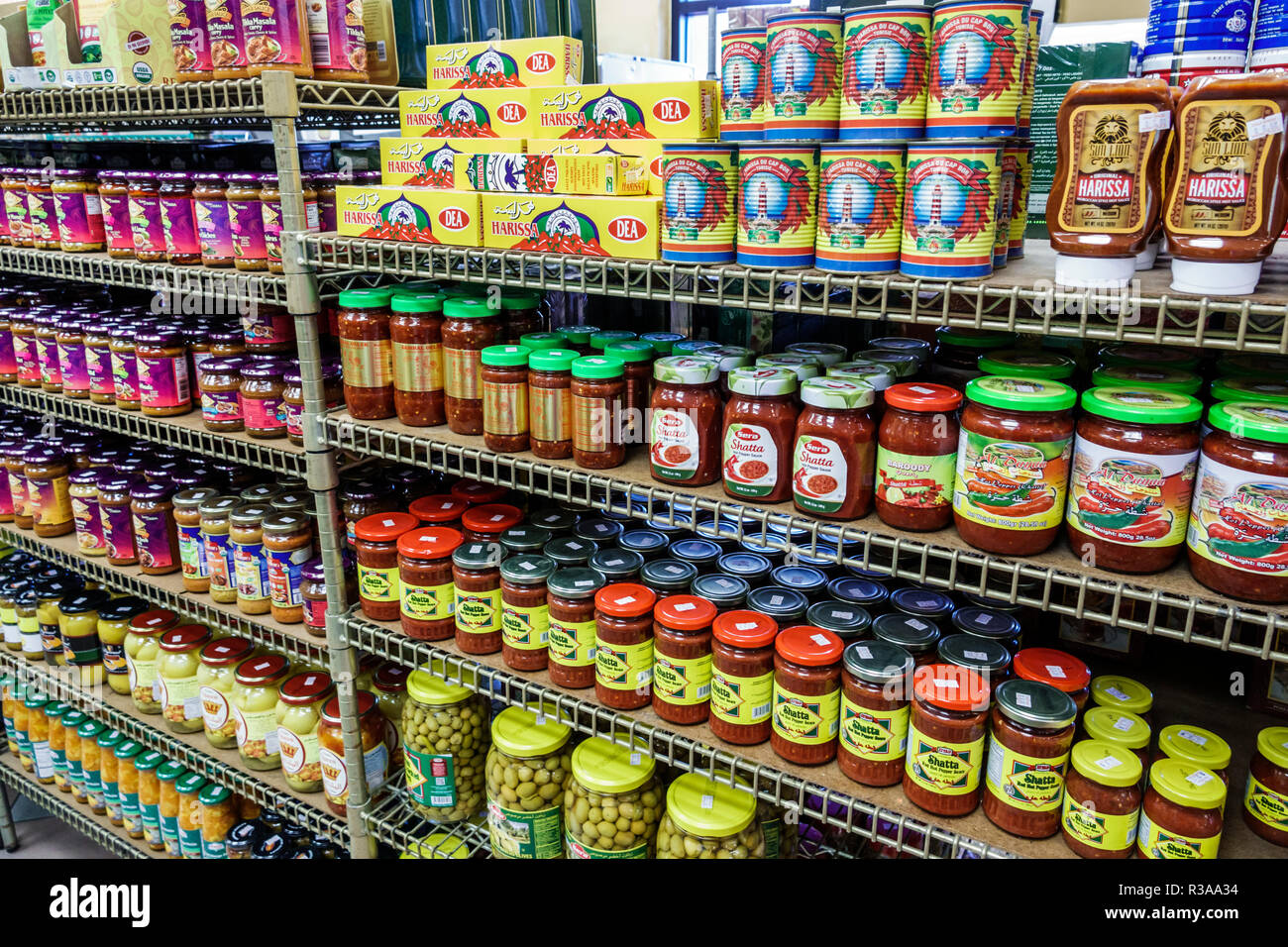

3. Shelving and Racking Systems: Proper storage is essential for small businesses with limited space. Invest in shelving and racking systems to maximize vertical storage space and keep materials organized. These systems can be customized to fit your specific needs, whether you’re storing products, inventory, or supplies.

4. Carts and Dollies: Utility carts and dollies come in handy for moving materials and products within a workspace. They can be particularly useful in retail settings, workshops, or small warehouses. Carts and dollies can be designed with features like shelves, bins, and handles for easy maneuverability.

5. Storage Bins and Containers: For efficient organization and storage of smaller items, small businesses can use storage bins and containers. These can be stackable and come in various sizes and designs. Clear bins allow for easy visibility of contents, while durable options ensure longevity.

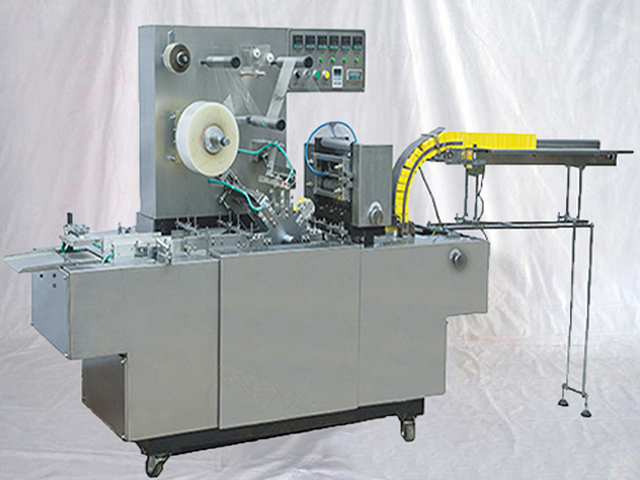

6. Conveyor Systems: While not as large or complex as those used by larger industries, small businesses can benefit from compact conveyor systems. These are particularly useful for assembly lines and packing operations, helping to move products along efficiently.

7. Scissor Lift Tables: Scissor lift tables are versatile lifting devices that can handle various material handling tasks. They can be used to raise or lower loads to a comfortable working height, making them suitable for tasks like packaging, assembly, and maintenance.

8. Storage and Workbenches: Combining storage and workspace, these versatile solutions are ideal for small businesses looking to optimize their material handling processes. They often include drawers, shelves, and work surfaces, providing a space-efficient way to store materials and perform tasks.

9. Forklifts (If Applicable): For small businesses with a higher volume of materials and larger facilities, compact forklifts designed for small spaces may be worth considering. These forklifts can handle palletized loads efficiently.

In conclusion, small businesses can enhance their material handling efficiency and organization by investing in the right equipment. The selection of equipment should align with the specific needs and space constraints of the business. By making smart choices and focusing on cost-effective solutions, small businesses can improve their material handling operations, reduce labor costs, and enhance overall productivity. Efficient material handling is not just a benefit but a necessity for the growth and success of small businesses.

![Building Brilliance: Unveiling the Premier Residential Construction Experts in [Your City]](https://readingcoremag.net/wp-content/uploads/2023/12/Depositphotos_26374913_m-2015.jpg)

0